As world´s first manufacturer, BASS opened up a new generation of coatings by introducing BT in 2014. Specially developed for thread production, the BT-coating scores from a standing position with an increase in performance of up to 100 %.

The BT-coating based on AlCrN can be used for a diversified range of applications (see below). The coating, applied by means of an innovative procedure, features special coating properties. Due to the high coating adhesion the probability of coat spalling is reduced. Furthermore, the coating´s extraordinary smoothness leads to less friction and thereby decreases of the polygon´s thermal load.

The BT-coating was specifically designed for threading tools which is why it innately convinces with remarkably high thermal resistance. Thus, along with the high coating hardness, BT achieves clearly longer tool lives and higher cutting speed compared with coatings based on titanium like TIN and TICN – and this in an enlarged range of materials.

The application of the BT-coating is possible on both powder metal (HSSE-PM) and solid carbide (VHM) tools. It can be employed in wet processing as well as in the use of minimum quantity lubrication (MMS).

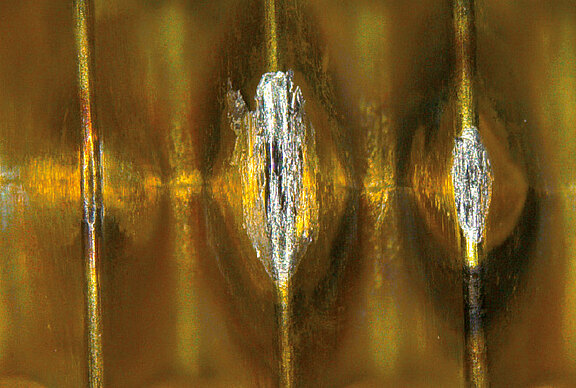

Pictures taken after 1,000 threads

Already after 1.080 threads, the TIN-tool has reached the end of its tool life and shows significant wear. There is no more coating at the polygon tips.

In contrast to that, the BT-tool only shows slight wear and enables the process-reliable production of 1.000 additional threads.

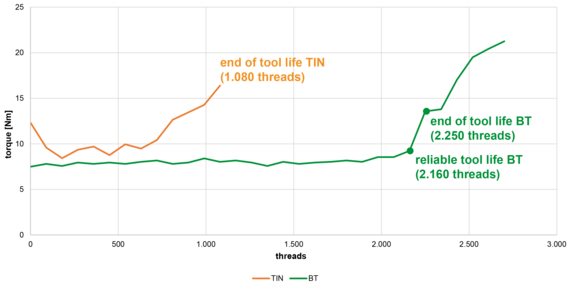

The torque curve shows the superiority of the BT coating over TIN. Whereas for BT, the running-in behaviour is smooth and stable from the early beginning, for TIN it takes time to stabilise. Even after that, BT runs for a very long time at a constant low torque level due to the coating properties.

Already after 600 threads, wear occurs in the TIN-coated tool along with an increase in torque. The identical tool with BT coating, however, runs smoothly and reliably over 2,000 threads. Even after a sharp increase in torque, several hundred true to gauge threads are still possible.